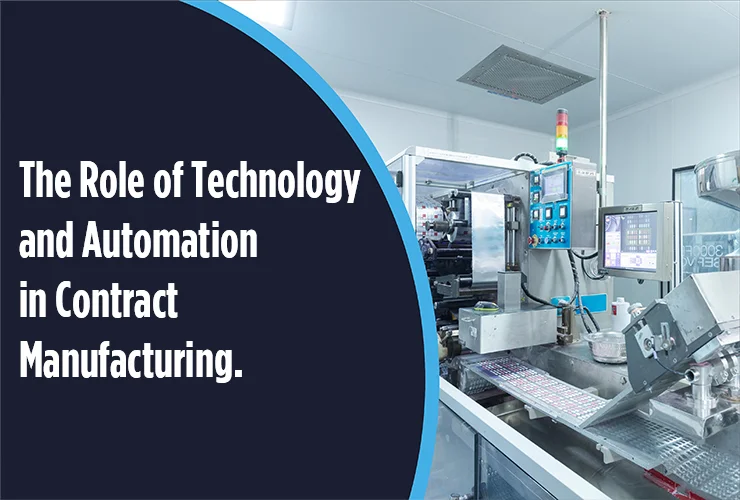

Being a successful contract pharmaceutical manufacturer means being able to ensure that a number of operations ranging from sourcing to manufacturing to quality check to storage and supplying the shipment to the clients take place efficiently one after the other or even simultaneously. To do all of this in a facility means that the manufacturing unit should be equipped with tools that rely on the latest technology and automation. While being dependent on cutting-edge technology is definitely advantageous for a manufacturing company, it is to be noted that human supervision is also a necessary component to ensure that all processes are taking place as expected. In this blog, let us understand why technology and automation are crucial for contract pharmaceutical manufacturing.

Need for technology and automation in contract pharmaceutical manufacturing

Optimized process: Human errors can be minimized using technologically advanced and automated equipment. Repetitive procedures can be done more precisely with automated machines as against using the workforce to do the same.

Enhanced traceability: Barcodes and RFID (radio frequency identification) systems are being increasingly used these days. With technologically advanced methods, tracing the origin of the raw material, different components of the pharmaceutical product, to the final product becomes easy with the click of a button. By this method, transparency can be maintained in the supply chain.

Time-saving: There is no denying that what humans can do in hours or days, automation and the latest robotic technologies can achieve in a matter of minutes (or sometimes seconds). The best part is that so much is achieved that too with the highest standards of quality that is difficult to do solely by depending on human endeavor.

Regulatory compliance: Complying with Good Manufacturing Practices (GMP) and other guidelines is facilitated by using technology-enabled procedures. By relying on electronic systems for documentation and record maintenance, regulatory compliance becomes easy as compared to maintaining all records on paper and doing it by hand.

Sterile environment: Maintaining sterile conditions is very important for manufacturing any dosage form as a slight oversight can cause significant wastage of the whole batch. This translates into a loss of resources, money, and time. To overcome this challenge, using automated systems that monitor the temperature, humidity, oxygen concentration, and sterility of the surroundings are much needed.

Why choose Akums Drugs & Pharmaceuticals Ltd?

Akums Drugs & Pharmaceuticals Ltd is the leading contract pharmaceutical manufacturer in India. For instance, the company uses automated capsule-filling machines as opposed to manual or semi-automated machines to fill in capsules with different formulations. This speeds up the whole process while ensuring consistency in quality. This is only one of the many ways that Akums utilizes automation and innovation. Its twelve state-of-the-art plants located in Haridwar, Kotdwar, and Baddi are all furnished with the most advanced technology that the world has at present. Since its inception in 2004, it has achieved various milestones that have been recognized by top-notch international and national organizations. Knowing that the company produces 140 million tablets in a day is rightly reflective of its leveraging technology and automation.